Sabcool Ice Maker

The ice maker is one of the essential equipment used in various industries, converting water into ice using its cooling system. This device can produce ice in various forms such as powdered, cubed, molded, and flaked. Different models of ice makers are used in various industries, including industrial companies, fisheries, fishing boats, concrete production, hotels, restaurants, slaughterhouses, banquet halls, and more.

In addition to high-speed ice production and the ability to produce ice in various shapes, industrial ice makers have other attractive features. They have compartments for ice storage, allowing you to produce and store ice in large quantities and use it whenever needed.

Vahid Refrigeration Industries Group is one of the leading and well-known manufacturers of these devices in the country, constantly producing various industrial ice makers with different shapes, dimensions, and capacities. If you’re looking for a quality industrial ice maker with suitable performance, you can contact this knowledge-based company and use their products.

Technical Specifications of Ice Makers:

- Body: The ice maker’s body is made of high-quality stainless steel sheet, which is highly resistant to rust, corrosion, and wear in humid environments.

- Compressor: The compressor is a crucial component of the ice maker, responsible for compressing the refrigerant gas. The type and brand of compressor play a significant role in the ice maker’s performance and efficiency.

- Condenser: The condenser converts compressed vapor into liquid and cools it down.

- Evaporator: This component absorbs heat from the compressed liquid, converting it into cool gas to chill the water and turn it into ice.

- Water Flow Control Valves: These valves regulate the water flow inside the industrial ice maker.

- 6. Electrical Valve: This valve is used in fluid control and transfer lines.

- Expansion Valve: This valve reduces the refrigerant gas’s pressure and temperature rapidly, transferring it to the evaporator.

- Refrigerant Gas Tank: This tank is designed to store the refrigerant liquid.

- Pressure Control and Thermostat: These devices control the industrial ice maker’s pressure and temperature.

- Dryer Filter: This filter absorbs moisture inside the refrigeration circuit in the ice maker.

- Pump: It directs water into the ice maker to be frozen, and after freezing, the crushed ice is transferred to the storage tank.

Operation of Ice Makers:

Industrial ice makers generally have a similar mechanism of operation. Initially, purified water enters the ice maker through inlet pipes. Some of them have a part called a purifier that automatically purifies water if it contains excessive salts or is unhealthy. The amount of water entering the device is adjustable and controlled by a control valve.

The general operation of ice makers is as follows:

– Water enters the device and is controlled and regulated by the control valve.

– The incoming water is directed by the pump to the freezing chamber.

– In the freezing chamber, water turns into ice and returns to the device’s storage tank.

– The refrigerant gas is injected into the coil and evaporates.

– The compressor rotates the gas inside the system and sends it to the condenser to turn it into liquid.

– The refrigerant gas is directed through the compressor’s operator and then to the condenser to become liquid and finally enters the ice maker’s tank.

– The tank in the device monitors the ice level in proximity to the operator. The ice maker cools the water and begins the ice production process. Using pure water ensures that the ice is produced precisely at zero degrees Celsius or below.

– When the stored ice level in the ice storage reaches a specific point, the ice production process stops, and the device halts.

– The refrigerant, which has absorbed heat from the environment, is sent to the ice maker’s operator by an electrical valve and an expansion valve to produce ice. This process continues until the device’s tank is fully filled.

As a result, industrial ice makers have the ability to efficiently produce ice using this mechanism, serving various needs in different locations.

Ice Maker Production:

Vahid Refrigeration Industries Group is a knowledge-based company with over 45 years of experience in designing and producing various refrigeration equipment, including ice makers. With a diverse range of ice-making machines, Saabcool provides its customers the opportunity to procure the required ice types according to their needs. The ice makers produced by Saabcool include various types such as:

- Flake Ice Makers

- Plate Ice Makers

- Powdered Ice Makers

- Molded Ice Makers

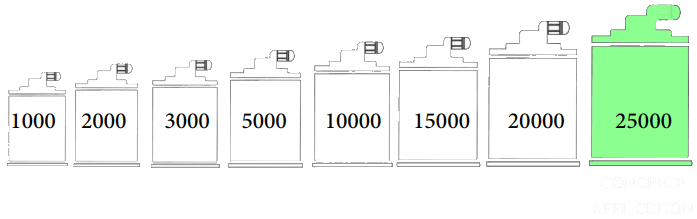

Each of these machines has the capability to produce ice with capacities ranging from 1000 kilograms to 50000 kilograms in 24 hours.

Depending on the ice’s intended use, Vahid Refrigeration Industries Group recommends customers choose the appropriate ice maker. These machines, with their combinations, also offer the ability to increase ice production capacity. Our engineers are constantly striving to improve and upgrade ice maker production technologies to provide quality and suitable equipment in this field.